Canned Preservation Principle (4) – Cans Double Seam Seal

Published date and time: 2020-01-07, 11:21

Date and time of modification: 2020-02-01, 12:25

Author: Food-Men

This article introduces the sealing process, method and principle of the can body and lid, and basic elements of the sealing mechanism. The “Canned Preservation Principle (4)” describe the formation process, structure and terminology of double seam.

1. Can Sealing Principle and Method

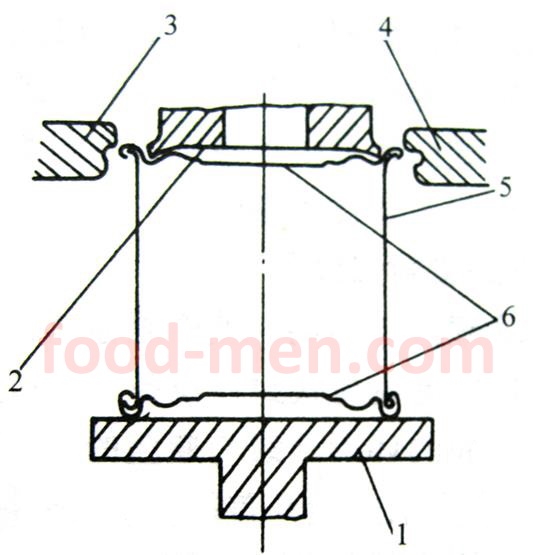

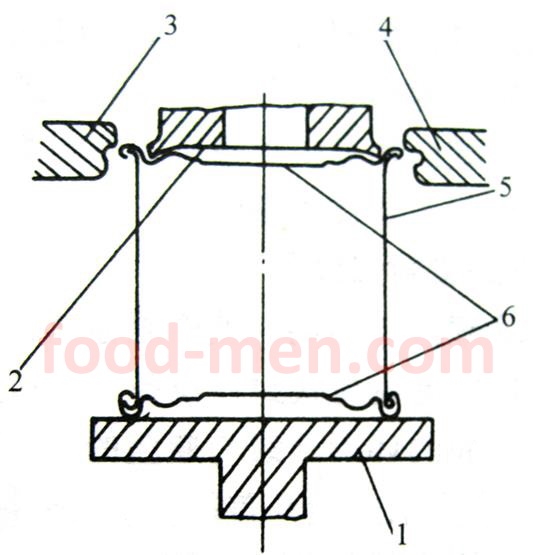

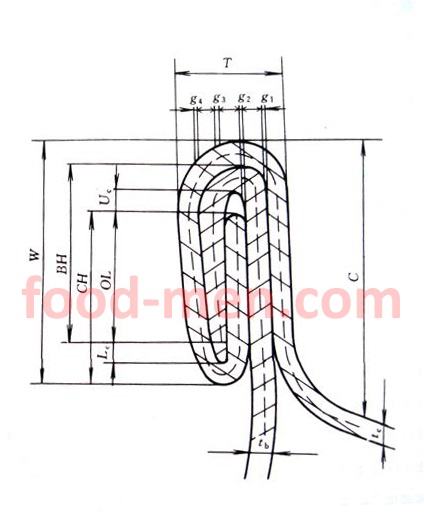

Canned preservation principle figure 1: Double seam structure

On the left side of the figure is the double seam anatomy of the can. The can body and the lid are tightly curled together. The gap between the can body and the lid is filled with sealant. In this way, the inside of the can is completely separated from the outside world.

(1) The basic elements of the sealing mechanism

Canned preservation principle figure 2: Basic elements of sealing mechanism

In the figure 2

1 --- Base plate (turntable). Hold the can body and lid together with the chuck. Ensure that the can body and lid will not move or rotate during sealing.

2 --- Chuck. Hold the can body and lid together with the base plate. Ensure that the can body and lid will not move or rotate during sealing.

3 --- 2nd roller. It is responsible for gradually pressing the curled shape, until pressed. Therefore, the sealing groove of the second roller is shallower.

4 --- 1st roller. It is responsible for the better curling shape of the can lid and body. But the curled shape (double seam) is not compressed. Therefore, the sealing groove (curling groove) of the first roller is deeper.

5 --- Can body

6 --- Can lid

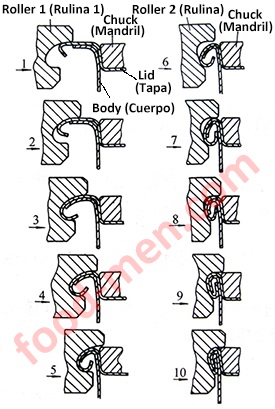

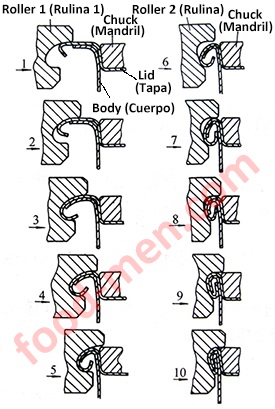

(2) The forming process of double seam

Canned preservation principle figure 3: The forming process of double seam

As shown in the figure above, the chuck just presses on the lid of the can, and the dimensions of the chuck and the lid match well. The figures 1 to 5 are the sealing process of the first roller, which is responsible for the better curling shape of the can lid and body. But the curled shape (double seam) is not compressed. Therefore, the sealing groove (curling groove) of the first roller is deeper. The figures 6 to 10 are the working process of the second roller, which is responsible for gradually pressing the curled shape, until pressed. Therefore, the sealing groove of the second roller is shallower.

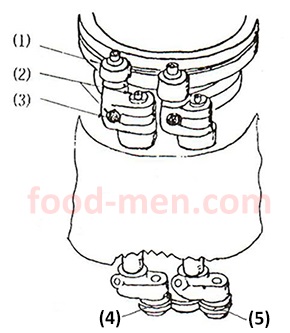

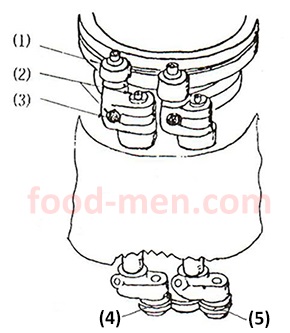

(3) Sealing operation method

It can be divided into two kinds of methods: The can body self-rotates, and the can body does not rotate.

Canned preservation principle figure 4: The can body self-rotates

a) The can body self-rotates: when the sealing operation is performed, the can body is self-rotates automatically, and the two sealing rollers move towards the can body. The structure of this type of seamer is relatively simple and mainly "the cam mechanism" is applied so that two sealing rollers can do the job. See the image above. However, as the can body rotates, it is easy for the liquid inside the can to splash. Therefore, this method is mainly used for sealing an empty can bottom lid.

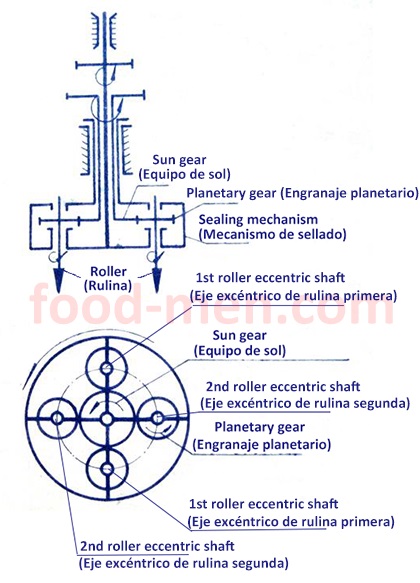

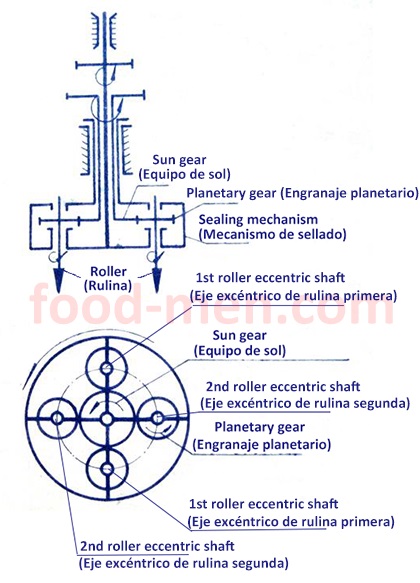

Canned preservation principle figure 5: The can body does not rotate

b) The can body does not rotate: When two rollers operate the seal, the can body does not rotate, the rollers rotate around the can body to curl the double seam. The structure of the seamer is relatively complex and mainly the work of the sealer is carried out through the “eccentric mechanism of the planet gear”. See the image above. It is suitable for sealing the cylindrical can and the irregularly shaped can, as well as the can containing broth.

2. Seamers or Sealers for Can Double Seam

(1) FG-8H Automatic Cans Double Seam Seamer or Sealer: Can seal the bottom or top lid of the can body. The FG-8H cans double seam sealer (seamer) is machinery of empty cans or cans filling.

(2). FMG-6H Automatic Cans Double Seam Seamer or Sealer: Is machinery of empty cans or cans filling, can seal the bottom or top lid of the can body.

(3). Automatic Big Cans Double Seam Seamer or Sealer: It is specially designed for the sealing of large cans, and can seal the bottom or top lid of the can body.

(4). FK-4 Automatic Vacuum Seamer or Sealer for Cans Double Seam: Can automatically transport cans, place lids and seal, and can be connected with other machines to form automated making line.

(5). FK-30 Automatic Vacuum Seamer or Sealer for Cans Double Seam: It has a lid pre-sealing system, which makes the cans double seam vacuum sealer run more stable and higher speed.

(6). FK-D25 Automatic Vacuum Seamer or Sealer for Big Cans Double Seam: Is used for sealing large diameter tinplate cylindrical cans. Each can weighs up to 3.5 kg.

(7). Automatic Vacuum Seamer or Sealer for Irregular Cans Double Seam: Is suitable for sealing cans except for cylindrical cans.

(8) SCP-24 Lab Cans Double Seam Seamer or Sealer: Can automatically seal the can by pressing the lifting handle.

3. The structure and terminology of the double seam

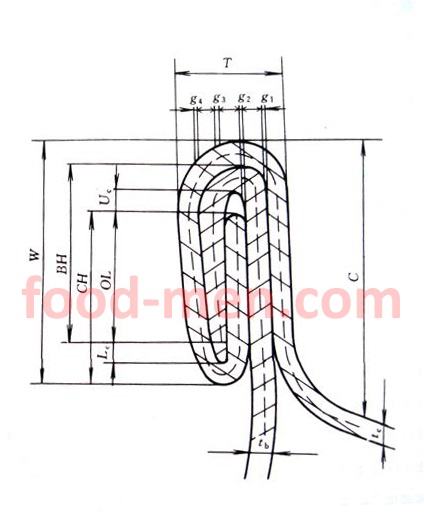

Canned preservation principle figure 6: The structure of double seam

In Figure 6:

•T — Seam thickness

•W — Seam lenght

•C — Countersink depth

•BH — Body hook lenght

•CH — Cover hook lenght

•OL — Overlap length

•Uc — Cover hook gap

•Lc — Body hook gap

•G = g1 + g2 ++ g3 + g4 (the gaps of seam thickness)

•tb——thickness of the can body tin plate

•tc——thickness of can lid tin plate

4. Detection and calculation of double seam

(1) Crimping thickness gap: G = g1 + g2 + g3 + g4 (G is generally 0.15 ~ 0.25)

(1) seam thickness: T = 3tc + 2tb + G

(3) seam length: W = 2.6 tc + BH + Lc

(4) Countersink depth: C = W + 0.15 ~ 0.30 (This formula may not be used for easy opening lid and full opening lid)

(5) overlap length: OL = BH + CH + 1.1 tc-W

(6) overlap percent (OL%): Estimation formula of production site:

OL% = (BH + CH + 1.1tc -W) / (W -2.6tc-1.1tb) × 100%

Calculation formula of instrument detection:

OL% = 100% × OL / (OL + Uc + Lc)

The double seam quality index stipulates that the overlap percent OL (%) ≥50% (Of course, different cans types and different countries may be slightly different.)

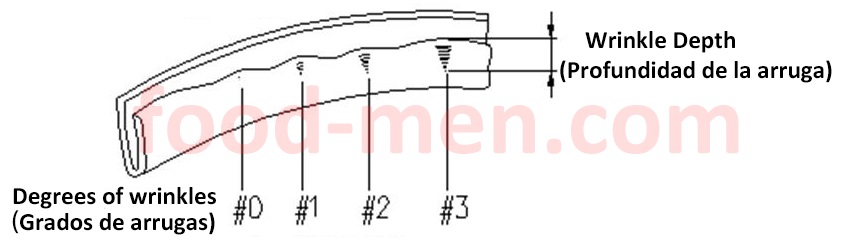

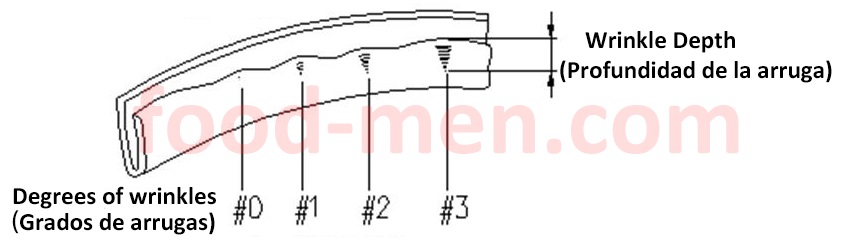

(7) Tightness rating (TR%): Cover hook wrinkle

Canned preservation principle figure 7: Tightness rating or Cover hook wrinkle

Tightness (TR%) = (1-Maximum wrinkle depth of the entire cover hook / length of the corresponding cover hook) × 100%

In the figure above, the tightness (or wrinkle degree of cover hook) is divided into # 0, # 1, # 2 and # 3, a total of 4 degrees.

# 0 --- Basically no wrinkles. Tightness (TR%) = 0

# 1 --- The depth of wrinkle extension is less than 1/4 of the length of the cover hook. Tightness (TR%) ≥ 75%

# 2 --- The depth of wrinkle extension is 1/4 to 1/2 of the length of the cover hook. Tightness (TR%) = 50% to 75%

# 3 --- The depth of wrinkle extension is more than 1/2 of the length of the cover hook. Tightness (TR%) ≤ 50%

The double seam quality index stipulates that the Tightness rating (TR%) ≥50%. (Of course, different cans types and different countries may be slightly different.)

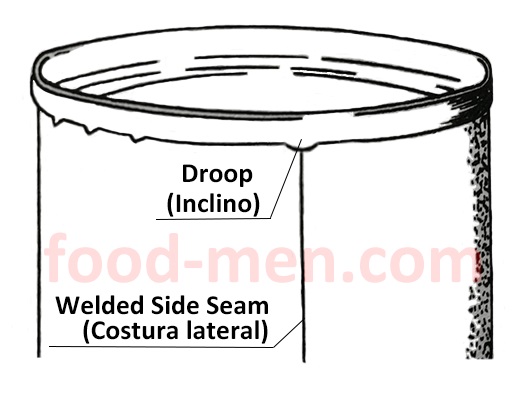

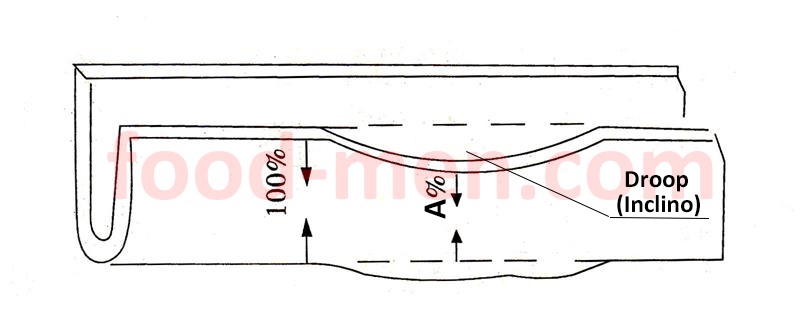

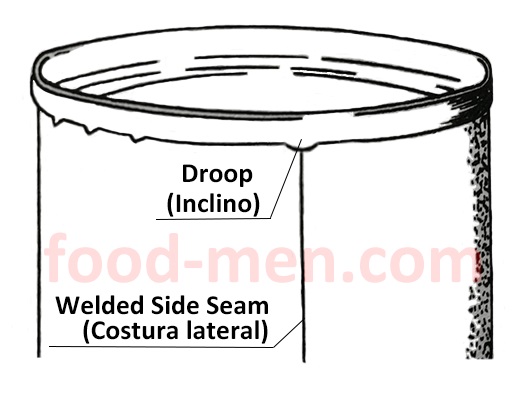

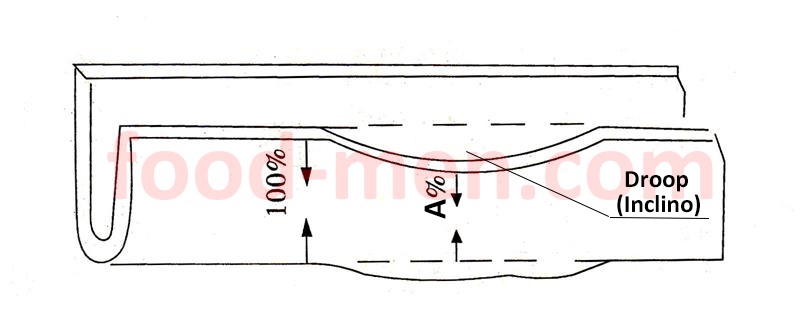

(8) Juncture rating (JR%): The drooping degree of the cover hook at the welded side seam of the can body.

Canned preservation principle figure 8: The drooping degree of the double seam at the welded side seam of the can body

Canned preservation principle figure 9: The drooping degree of the cover hook at the welded side seam of the can body

Since the side welded seam of the can body is overlapped by two tinplate sheets, the number of layers of double seam tinplate sheets here have increased. The sealing pressure of the roller here will increase. The cover hook at this place is squeezed to form a drooping lip, resulting in a reduction in the effective width of the cover hook. Observe the shape of the cover hook after the double seam is disassembled as shown in Figure 9. The JR% (A%) can be expressed by the following formula:

JR% = (1- The drooping degree of the cover hook at the welded side seam of the can body / normal cover hook length) × 100%

The double seam quality index stipulates that the juncture rating (JR%): ≥50% (Of course, different cans types and different countries may be slightly different.)

The detection and calculation of double seam is an important part of quality control in canning production.

5. Common inspection tools and instruments for can double seam

(1) YGTQ-1 Can Double Seam Inspection System

The YGTQ-1 can double seam inspection system is a testing instrument for anatomic double seam. It consists of YGS-1 can double seam thickness inspection instrument, CSG-1 can double seam countersink inspection gauge, CUT-1 can double seam cutting saw machine, double seam photodetector, STR-10 can double seam stripper for inspection, calibration gauge block, computer and testing software.

(2) YGTQ-2 Can Double Seam Inspection System

The YGTQ-2 can double seam inspection system is a testing instrument for anatomic double seam. It consists of CSG-2B can double seam countersink inspection gauge, can double seam inspection micrometer, double seam photodetector, CUT-2 can double seam cutting saw machine, calibration gauge block, STR-10B can double seam stripper for inspection, computer and testing software.

(3) Manual Inspection Tools for Can Double Seam

In the absence of a can double seam inspection system, the DC-001 Dial Caliper for Can Double Seam Inspection, and the Combination Plier for 2 or 3-piece Cans Inspection, and the Tinplate Scissor for 2 or 3-piece Cans Inspection together form a manual inspection tools, which can also accurately estimate the double seam structure and size of cans.

-----------------------------------------------------------

Articles of interest to food producers

(1) Food Commercial Sterility Testing Method and Analysis

(2) Food Commercial Sterility Testing and Equipment

(3) Method of Aerobic Plate Count

(4) Equipment of Aerobic Plate Count

(5) Testing and Counting Method of Coliform Bacteria

(6) Equipment for Testing and Counting Coliforms

(7) Calibration method of length of microscope micrometers

(8) Online Food Container Quality Detecting Solution After Sealing

(9) Articles in the "Food Technology" section at the top left of this page

-----------------------------------------------------------