Hazard Analysis and Critical Control Point (HACCP) System and Guidelines for Its Application

Standard Number: GB/T19538-2004

Publish date: 2004-06-11

Implement date: 2004-09-01

Issued by: The General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, and the Standardization Administration of the People's Republic of China

Standard Status: currently valid

This is GB/T19538-2004, Hazard Analysis and Critical Control Point (HACCP) System and Guidelines for Its Application, Chinese food standard and regulation. It is issued by the General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, and the Standardization Administration of the People's Republic of China.

The English version of this standard is translated from the Chinese original GB/T19538-2004. In case of discrepancies in the translated version, the original Chinese standard GB/T19538-2004 (Chinese version) shall prevail. This translated version can provide reference for food production enterprises.

Standard Text of GB/T19538-2004

A. Standard Cover of GB/T19538-2004

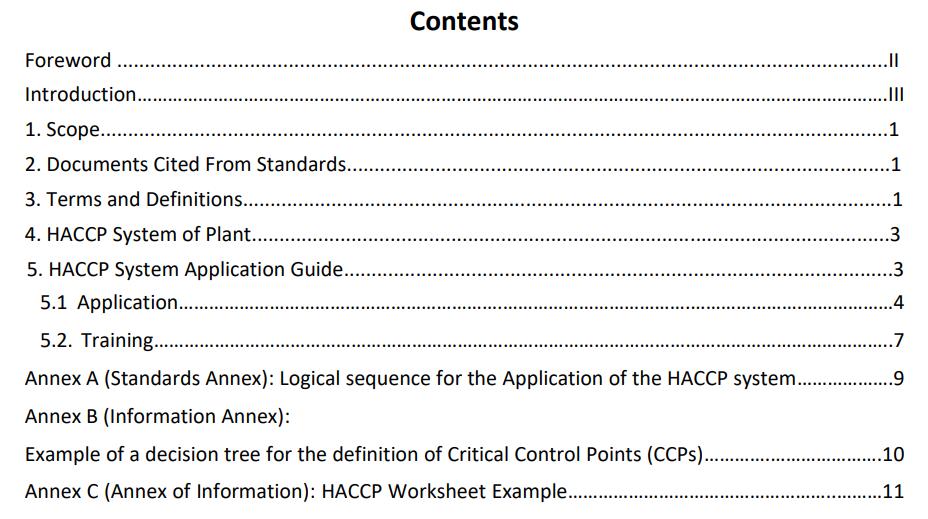

B. Table of contents

C. Standard Preface of GB/T19538-2004

Foreword

This standard is the same as the Annex to CAC/RCP 1'1969, Rev.3 (1997), Amd, 1999, IDT [Hazard Analysis and Critical Control Points (HACCP) and Guidelines for its Application] published by Codex Alimentarius Commission (CAC).

Annex A, Annex B and Annex C of this standard are editable modifications based on graphs 1, 2 and 3 in the CAC standard.

Annex A is a standards annex, Annex B and Annex C are information Annexes.

This Standard is drawn up by the China National Institute for Standardization.

This Standard is under the centralized management of the China National Institute for Standardization.

The main drafting entities are: China National Institute for Standardization, Registration Department of CNCA, China National Commission Certification Body(CNAB), National Technical Committee on Food Industry of Standardization Administration of China, CIQ Hebei.

Main drafters are: LIU Wen, SHI Xiaowei, YANG Li, LIU Junhua, WANG Jing, LIU Xiaohong, HAO Yu, GAO Yongfeng. This Standard supersedes GB 14880-1994

D. Standard Introduction of GB/T19538-2004

Introduction

This Standard defines the principles for the Hazard Analysis and Critical Control Points (HACCP) System adopted by CAC. Considering that the specific application of the system varies due to the difference in the food operating environment, Guidelines for its Application are confirmed [1]

The HACCP System is based on science and systematization, identify specific risks and determine control measures in order to ensure food safety. HACCP is a tool to assess the risk and build the control system, its emphasis is not to depend on the inspection of final products but prevention. Any HACCP system must have the ability to adapt to changes, for example, improvements in equipment design, processing measures, and technology development.

The HACCP system can be used in the food chain [2] from primary production to final consumption, guided by scientific evidence in favor of human health risk. At the same time of improving food safety, there will be other benefits from the application of the HACCP system, in addition to which, it is also conducive to conducting inspection for government entities, and promoting international trade through enhancing the credibility of food safety.

For the successful application of the HACCP system, the full commitment and participation of managers and employees is required. Forms of study from multiple disciplines are needed according to specific study objects, which in general should include professional knowledge and skills in agriculture, veterinary health, manufacturing science, microbiology science, medicine, public health, food work, environmental health, chemistry and engineering. the HACCP application is compatible with the quality management system (for example: ISO 9000), and in this case, the HACCP application is the food safety management system.

In this standard, HACCP is for food safety, but the principle can be used for other aspects of food quality.

______________________________

[1] The principle of the HACCP system is confirmed on the basis of HACCP usage requirements, this standard provides guidelines for its application.

[2] Before using HACCP in any department of the food chain, that department must obtain preconditions, for example, it complies with national and international food output standards and has been verified.

______________________________

E. Standard Content of GB/T19538-2004

Hazard Analysis and Critical Control Point (HACCP) System and Guidelines for Its Application

1. Scope

This standard determines principles and application guidelines for hazard analysis and critical control points.

This standard is used for the complete food chain that is from food production to final consumption.

The HACCP of this standard is aimed at food safety.

2. Documents Cited From Standards

The clauses of the documents mentioned below become clauses of this standard through being cited by this standard. For all documents cited with dates, all modifications (with the exception of error corrections) or modifications are not applicable for this standard, but all parties who conclude the agreement on the basis of this standard are still encouraged to study the possibility of whether or not to adopt the new versions of the aforementioned documents. Documents without dates and their new versions are applicable for this standard.

Guidelines on the application of GB/T 19001-2000 for the food and drink industry

3. Terms and Definitions

……

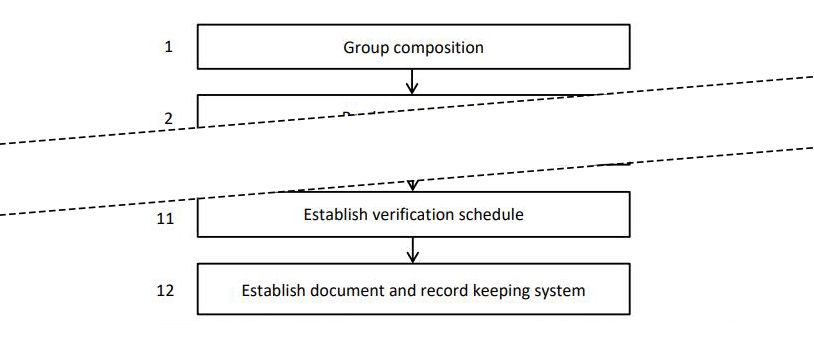

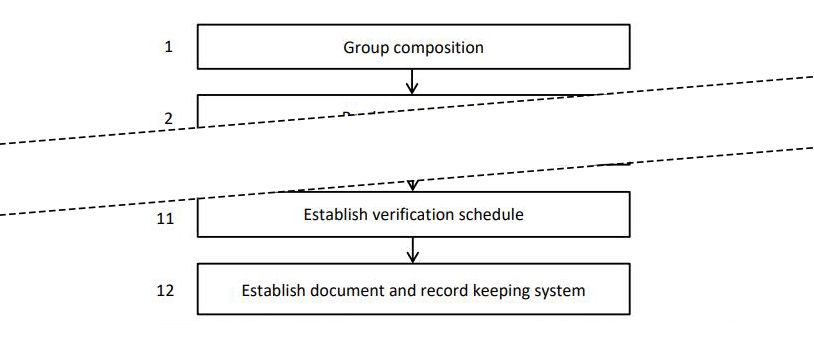

Annex A (Standards Annex)

Logical sequence for the Application of the HACCP system

……

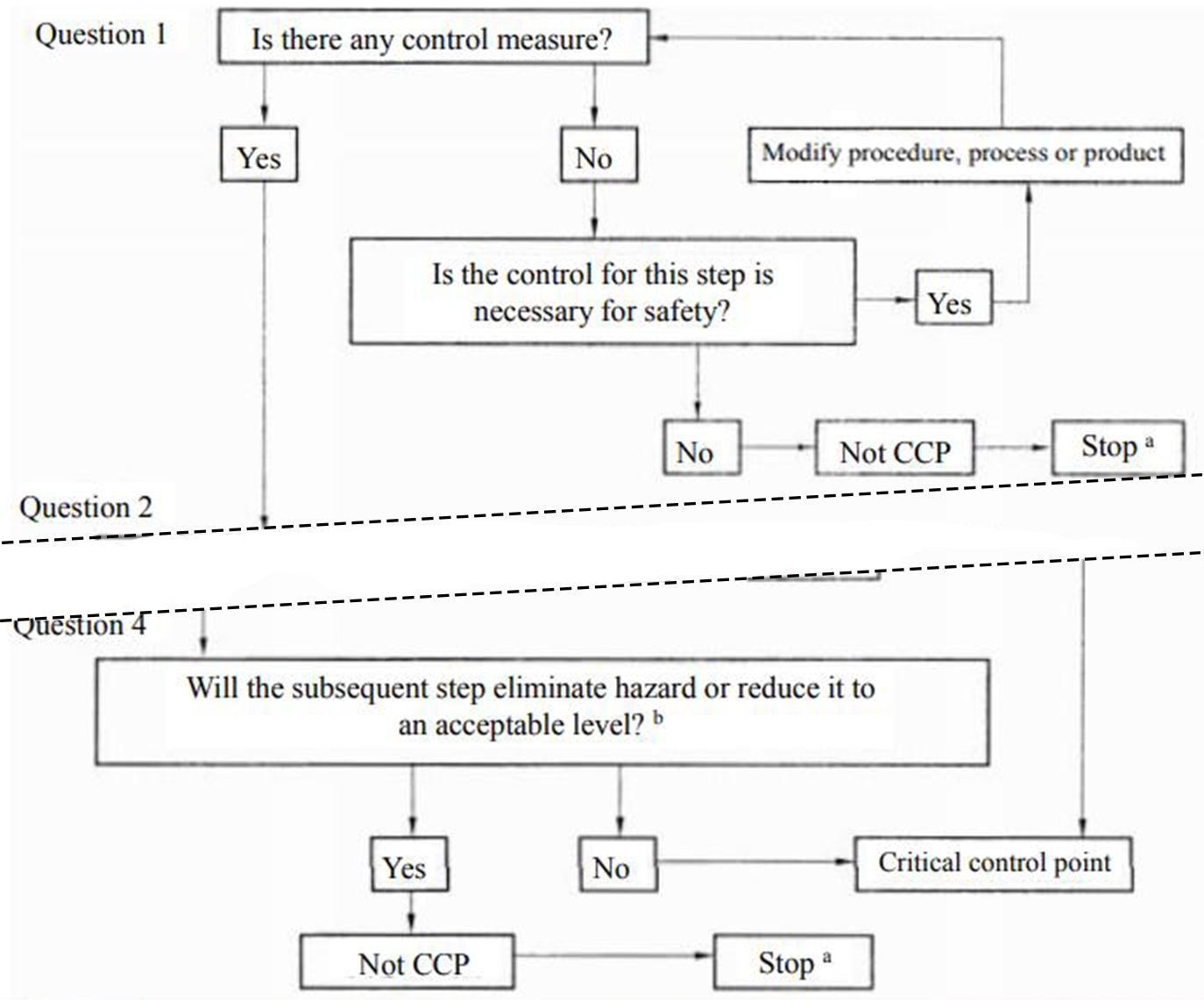

Annex B (Information Annex)

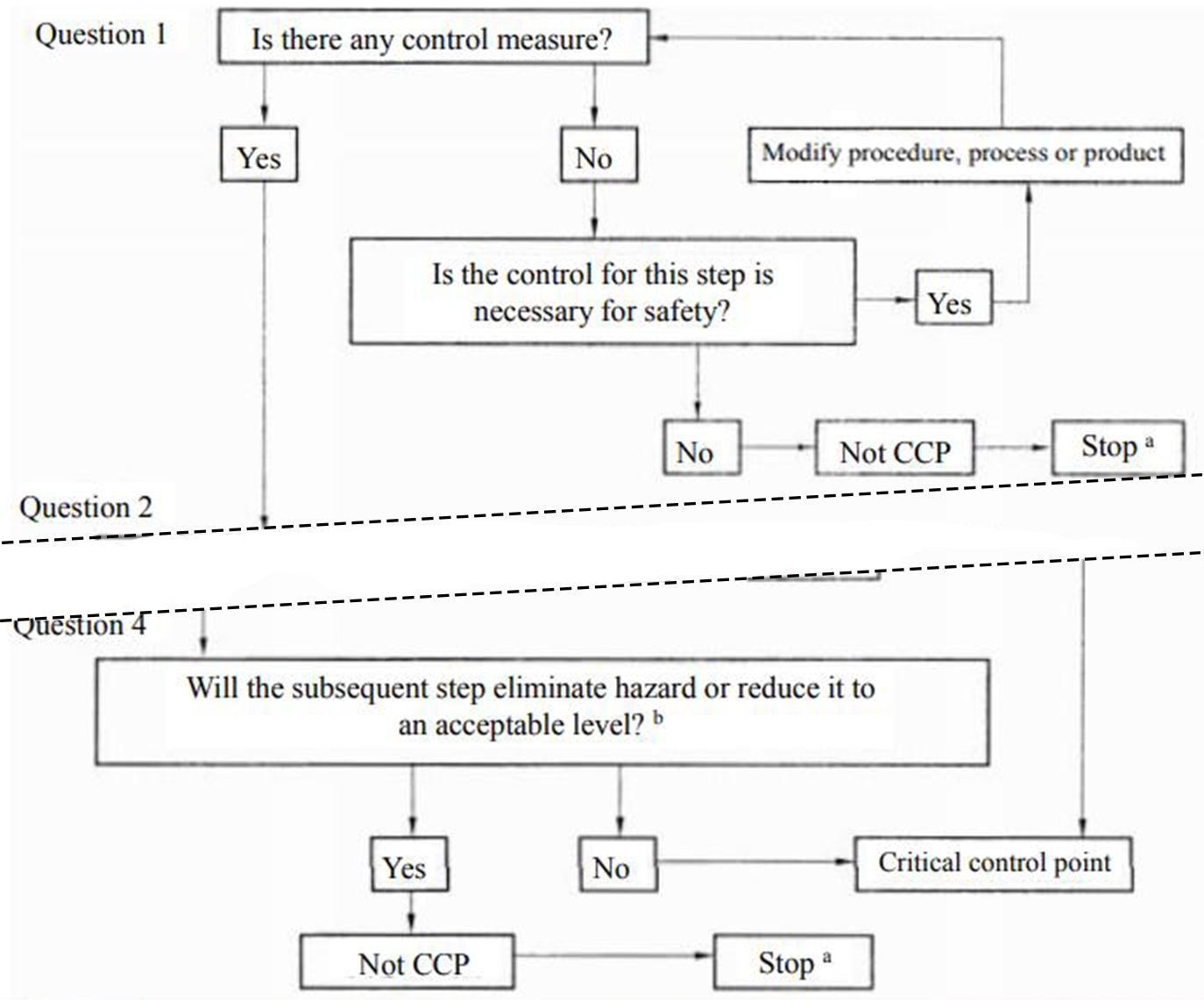

Example of a decision tree for the definition of Critical Control Points (CCPs)

Answer questions in order:

……

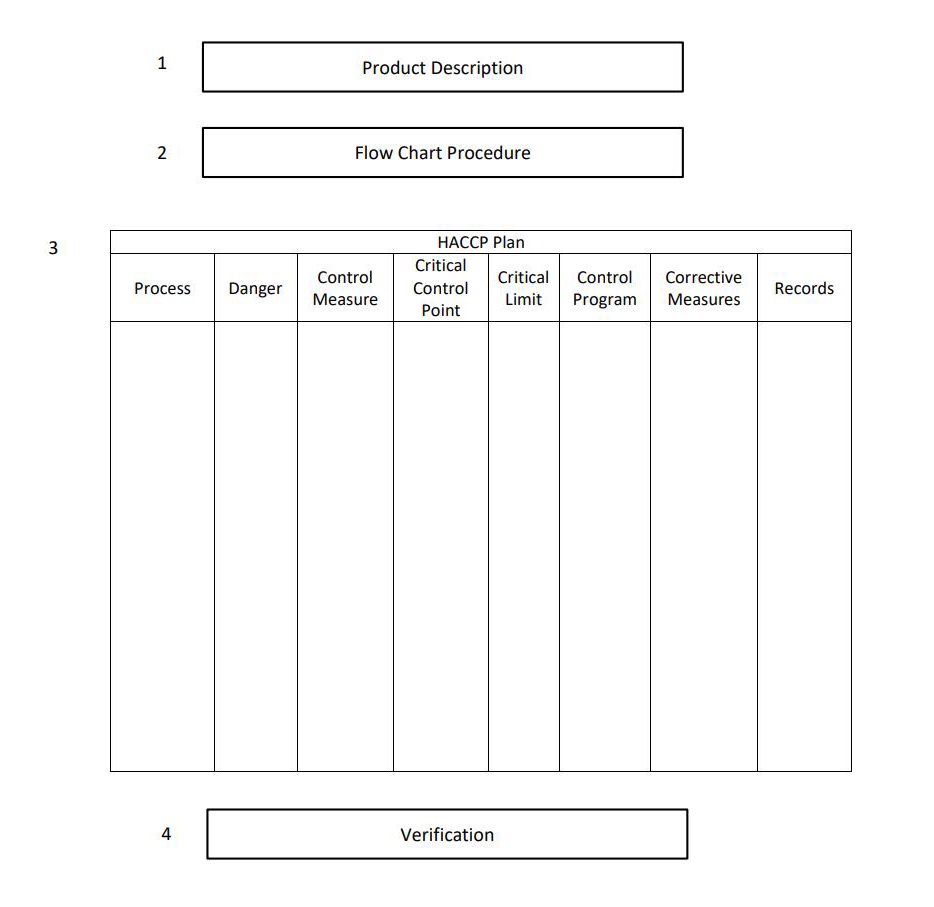

Annex C (Annex of Information)

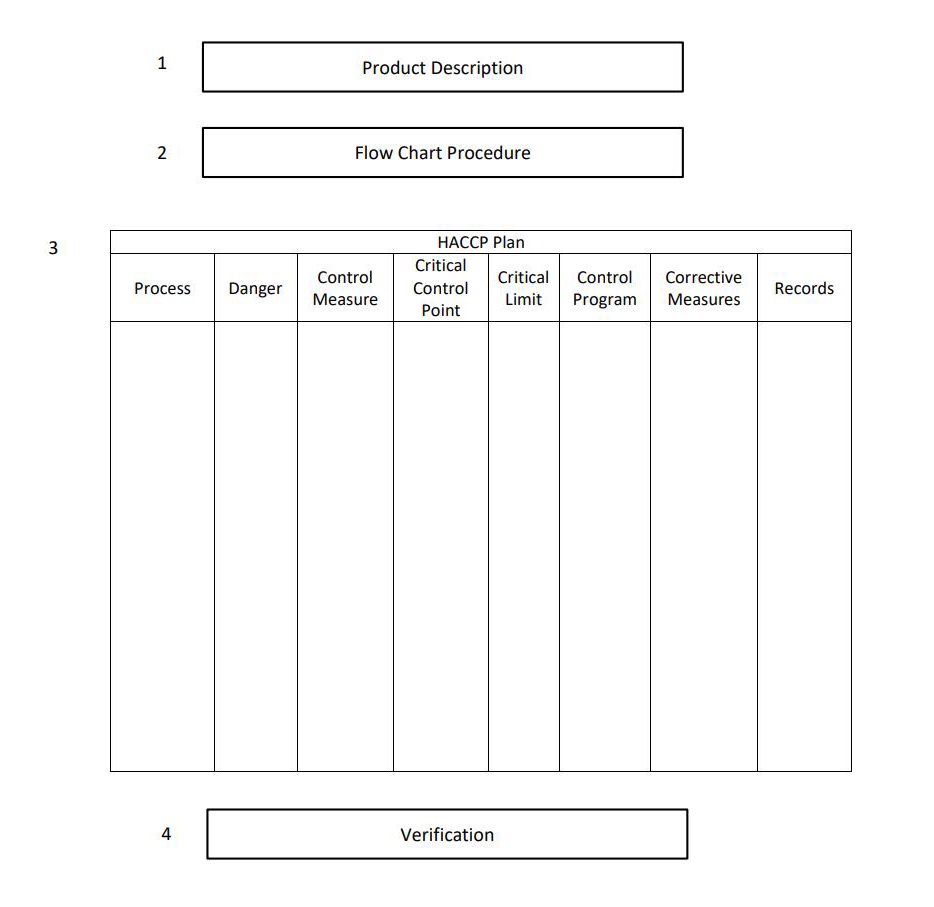

HACCP Worksheet Example

……

________________________

Note: Commonly used Chinese food standards include mandatory national standards (the code starts with "GB") and recommended national standards (the code starts with "GB/T")

If you need other Chinese standards related to food, please "Contact Us". We do our best to find and provide translation services.

----------------------------------------------------

To obtain the text of this standard (English version), a payment of 80 US dollars ($80) is required. Payment can also be made in RMB, Euro, British pound, Australian dollar, New Zealand dollar, Canadian dollar, Thai baht, Swiss franc, and ruble. Payment can be made by Visa, UnionPay, credit card, debit card, wire transfer, Paypal, Alipay and WeChat. After payment, please tell us your payment name, country and location where payment is made, payment time, and email address for receiving documents in "Contact Us". If you still haven't received the document after 1 day after payment, please "contact us" so that we can solve it in time. When the document is received, please reply "Document received". If there is no response within 10 days, we consider the document to have been received. You can also ask for help through "Contact Us".

----------------------------------------------------

References Articles

1. Hazard Analysis and Critical Control Point (HACCP) System - General Requirements for Food Processing Plant

2. General Hygienic Regulation for Food Production - National Food Safety Standard

3. GB5749—2022 Standards for Drinking Water Quality

4. Determination of Tin in Food 1 - National Food Safety Standard

----------------------------------------------------

Related Testing Equipment

1. Food Safety Testing and Inspection instruments Equipment: are used for inspection of pesticide residues, heavy metals.

2. Microbiology Testing Equipment and Instruments: include incubators, gadgets, and instruments, are one of the food safety testing equipment.

3. Laboratory Equipment and Instruments: include precision weighing equipment, evaporators, drying ovens and food testing instruments.

4. Food Production Monitors and Online Detectors: are capable of detecting and monitoring the quality of each product on the food production line, is important testing equipment.

----------------------------------------------------